"collision of hardware and software" entries

Tobias Kinnebrew on robots as paint brushes

The O’Reilly Solid Podcast: How using robots for artistic purposes changes the way we perceive art.

Subscribe to the O’Reilly Solid Podcast for insight and analysis about the Internet of Things and the worlds of hardware, software, and manufacturing.

The short film Box caused a sensation in 2013 by effortlessly blending industrial robots and projection mapping — physical and digital. Bot & Dolly, the studio behind Box, specialized in robotic cinematography until it was bought by Google in 2013, becoming part of Google Robotics.

Sometimes overlooked amid the spectacular effects it developed in-house was the significance of Bot & Dolly’s software platform: it was an abstraction layer that worked as a plug-in for Autodesk’s Maya design software, putting otherwise arcane industrial robots in the hands of any production designer who could wield a mouse.

In this episode of the Solid Podcast, David Cranor and I talk with Tobias Kinnebrew, strategist at Google Robotics and formerly the director of product strategy at Bot & Dolly and principal creative director for HoloLens at Microsoft. Read more…

Jim Stogdill on cloud-based typewriters and smart watches

The O’Reilly Solid Podcast: Distractions, wearables, and reference peanut butter.

Subscribe to the O’Reilly Solid Podcast for insight and analysis about the Internet of Things and the worlds of hardware, software, and manufacturing.

In this episode of the Solid Podcast, David Cranor and I talk with Jim Stogdill, one of the key figures behind the launch of our Solid conference, about some of the cool pieces of hardware that we’ve come across recently.

Stogdill starts off with the Hemingwrite, an ultra-simplified Internet-connected typewriter for writers who need to isolate themselves from distraction. It duplicates, at significant expense and austerity, a small part of any modern computer’s functionality. The Hemingwrite’s existence — along with that of its oversubscribed Kickstarter campaign — demonstrates the new economics of hardware: development costs have fallen enough that clever entrepreneurs can isolate and solve niche consumer problems like needing a browserless computer because you sometimes don’t want to be distracted by your browsered computer. Also, I’d like one. Read more…

Ben Einstein on accelerating hardware startups

The O’Reilly Solid Podcast: A discussion about critical issues for hardware startups.

Subscribe to the O’Reilly Solid Podcast for insight and analysis about the Internet of Things and the worlds of hardware, software, and manufacturing.

Hardware is getting more accessible, which makes hardware startups more appealing. A small team can develop a viable prototype for a simple product on a few hundred thousand dollars, and even tricky problems like autonomous cars are within the reach of startups.

Incubators and accelerators like Highway1, Lemnos, and HAX have played an important role in making hardware accessible; they help their portfolio companies work through the tricky engineering, manufacturing, and marketing problems that software startups don’t have to deal with.

In our new episode of the Solid Podcast, David Cranor and I have a wide-ranging discussion with Ben Einstein, co-founder and managing director of Bolt, one of the leading hardware startup accelerators.

Einstein, who spoke at Solid 2015 in California, talks about the importance of hardware marketing and customer development, including branding, crowdfunding, and virality (which is “much more possible with hardware now than it was 10 years ago,” he says). Read more…

How the IoT will transform manufacturing

The products of the future will impact not just factories, but all aspects of business.

Register now for Solid Amsterdam, October 28, 2015, where Dirk Slama will present the session “Managing the ‘Clash of Two Worlds’ in the IoT.” Editor’s note: this post is an excerpt from “Enterprise IoT: Strategies and Best Practices for Connected Products and Services,” by Dirk Slama, Frank Puhlmann, Jim Morrish, and Rishi M. Bhatnagar.

In some cases, a distinction is made between the industrial IoT and the consumer IoT. But when we talk about “Enterprise IoT,” our focus is less about specific application domains and more about openness and integration maturity.

In some cases, a distinction is made between the industrial IoT and the consumer IoT. But when we talk about “Enterprise IoT,” our focus is less about specific application domains and more about openness and integration maturity.

Here, we will take a closer look at some of the more industrial applications of Enterprise IoT, starting with a discussion about how IoT will transform manufacturing from the perspective of both product engineering and production technology.

Integrated production for integrated products

We believe that the IoT will have two main areas of impact on the current manufacturing landscape. The first concerns the organizational structure that is required to produce truly integrated IoT solutions. The IoT involves a clash between two worlds in which those in the machine camp and those in the Internet camp will be required to work together to create products that combine physical products with Internet-based application services. In an IoT world, many companies will discover that being just a manufacturing company or just an Internet company will no longer be sufficient; they will need to become both — or become subsumed in an ecosystem in which they play a smaller role. Read more…

Coming up at Solid Amsterdam

A look at our unified program for unified creators.

Register now for Solid Amsterdam 2015, our conference exploring the intersections of manufacturing, design, hardware, software, and business strategy. The event will take place in Amsterdam on October 28, 2015.

Creating a great product means knowing something about many things: design, prototyping, electronics, software, manufacturing, marketing, and business strategy. That’s the blend that Solid brings together: over our one-day program at Solid Amsterdam on October 28, 2015, we’ll walk through a range of inspiration and insight that’s essential for anyone who creates physical products — consumer devices, industrial machines, and everything in between.

Start with design: it’s the first discipline that’s called on to master any new technology, and designers whose work has been confined to the digital realm are now expected to understand hardware and connected systems as well.

Design at Solid begins with our program co-chair, Marko Ahtisaari, who was head of product design at Nokia from 2009 to 2013, and is now CEO and co-founder of The Sync Project. We’ll also hear from Thomas Widdershoven, creative director at Design Academy Eindhoven and co-founder of thonik, a design studio whose work specializes in interaction and motion design. Read more…

At Solid San Francisco, you could see all the way to the future

Making sense of the intersection between connected devices, accessible hardware, and synthetic biology.

Register for Solid Amsterdam, October 28, 2015 — space is limited.

I don’t usually describe conferences as “mind expanding,” but in this instance, the description is justified. At O’Reilly’s Solid 2015: Hardware, Software & the Internet of Things, held recently at Fort Mason in San Francisco, I encountered startling views of the future, thoughtful presentations on creative combinations of exciting new technologies, and warnings about what might happen if somehow it all goes wrong.

Dozens of speakers and presenters covered topics ranging from synthetic biology to augmented reality helmets to 3D printed automobiles. The audience was a mix of software developers, hardware designers, traditional manufacturers, digital manufacturers, academics, entrepreneurs, and venture capitalists keen to spot the next major tech trends.

The conference was organized around multiple tracks and themes, including data, design, software, hardware, product development, manufacturing, biology, security, technology, and startups. What follows is an overview of my key takeaways. Read more…

What to see at Solid

A look at the interdisciplinary learning paths you'll find at Solid.

Flipping through the schedule for our Solid conference, you might wonder why we offer talks on synthetic biology in the same program that includes sessions on smart factories and how to ship goods within supply chains. The answer is that Solid is about a nascent movement — new hardware — that draws on a lot of different areas of expertise. It’s about access and the idea that physical things are becoming easier for anyone to create and engineer. Understanding hardware and the Internet of Things, then, is critical for every technologist and every company.

Solid’s program has emphasized interdisciplinary learning from the beginning; we’ve seen that a smart, accessible, connected world will need contributions from a lot of different backgrounds: designers, electrical engineers, software developers, executives, investors, entrepreneurs, researchers, and artists.

The keynotes that we’ve lined up will provide an overview, and a sense of how widely impactful this idea is; they touch on design, manufacturing, urban futures, synthetic biology, government, innovation, and techno-archaeology (a topic we’ve explored in the Solid Podcast). And they’ll wrap up with a thought-provoking talk — with a demo — on how we experience flavor.

After lunch on Wednesday and Thursday, the program gets broad.

I’ve drawn up a handful of paths that you might consider taking as you go through Solid next week. None of these is a comprehensive program, but they’ll serve as jumping-off points for different members of the new hardware community. Read more…

Pop-up factory

An experiment at Solid tests a manufacturing style pioneered by pirates.

A few years ago, I was lucky enough to take a tour of the South China manufacturing ecosystem with Andrew “bunnie” Huang. One of the most fascinating things that I saw there were the markets full of funny little mobile phones: Read more…

Tying software and hardware together through art

The O'Reilly Solid Podcast: Andy Cavatorta and Jamie Zigelbaum on art that combines physical and digital.

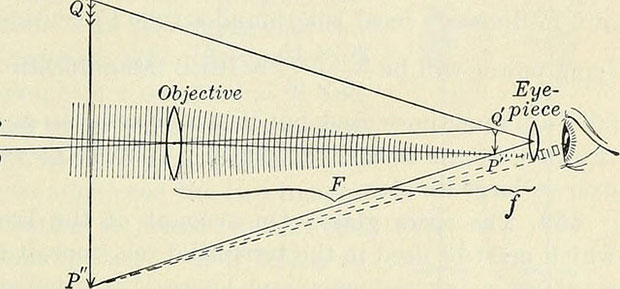

One of the theses behind our Solid Conference is that the stacks — the ranges of knowledge that technologists need to understand — are expanding so that the formerly separate disciplines of hardware and software are merging. Specific expertise is still critical, but the future lies in systems that integrate physical and virtual, and developing those effectively requires the ability to understand both sides at some basic level.

Installation art is a great place to look for those seamless integrations, and we’re excited to feature a couple of interesting installations at Solid. Our latest episode of the Solid Podcast takes us to Flatbush Avenue in Brooklyn, home to a collective of designers and engineers called Dark Matter Manufacturing, where David Cranor and I spoke with Andy Cavatorta and Jamie Zigelbaum. Cavatorta and Zigelbaum both create installations; Cavatorta works with sound and robotics, and Zigelbaum’s projects explore communication and interaction.

Cavatorta’s Dervishes installation will appear at O’Reilly Solid, June 23-25. He will also speak on “Music, machines, and meaning: What art teaches us about robotics and networks.” Read more…

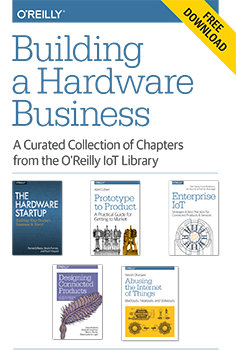

Building a hardware business

A free compilation of chapter excerpts from our IoT library highlights the approachable complexity of hardware.

Download a free copy of “Building a Hardware Business,” a curated compilation of chapter excerpts from our IoT library.

Over the last few years, we’ve seen an astonishing change in what it takes to build a hardware business. Hardware remains hard — executing it well requires technical and marketing expertise in several fields — but the barriers that startups must cross have been lowered considerably.That change has come about as a result of several changes in the way the market approaches hardware.

- Customers, whether consumers or businesses, have become aware of what hardware and connected devices can do for them. The Internet of Things means more than connected refrigerators now. For consumers, it represents desirable products like the NEST thermostat and Apple Watch. For managers, it represents the highest standards of informed decision-making and operational efficiency in everything from delivery fleets to heavy machines to simple design-driven data.

- Connecting with those customers has become easier. Startups can sell directly to niche consumers through online channels with the help of Etsy, Tindie, and ShopLocket, which are vastly easier to deal with than big-box retailers. These platforms also return rapid market feedback and offer ways for companies to connect with their consumers and build communities without intermediaries.

- Funding has become available through new mechanisms at every stage. Crowdfunding helps entrepreneurs test their ideas in the marketplace and raise enough money for early development. Venture capitalists, impressed by recent exits and aware of the vast green fields awaiting the Internet of Things, are willing to invest. Supply-chain managers like PCH are willing to take equity stakes in return for invoice financing, addressing a critical cash-flow challenge that can be a big barrier to startups looking to have products manufactured in large quantities.