"intelligent manufacturing" entries

Listening for tired machinery

Cheap sensors and sophisticated software keep expensive machines running smoothly

Software is making its way into places where it hasn’t usually been before, like the cutting surfaces of very fast, ultra-precise machine tools.

A high-speed milling machine can run at 42,000 RPM as it fabricates high-quality machine components within tolerances of a few microns. Excessive wear in that environment can lead to a failure that ruins an expensive part, but it’s difficult to use physical means to detect wear on cutting surfaces: human operators can’t see it and detailed microscopic inspections are costly. The result is that many operators simply replace parts on a pre-determined schedule — every two months, perhaps — that ends up being overly conservative.

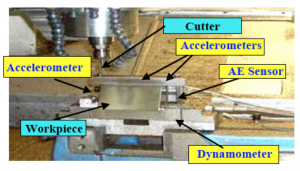

The researchers’ milling machine, shown with sensors near the cutting device. (Source: X. Li, M.J. Er, H. Ge, O. P. Gan, S. Huang, L.Y. Zhai, S. Linn, Amin J. Torabi, “Adaptive Network Fuzzy Inference System and Support Vector Machine Learning for Tool Wear Estimation in High Speed Milling Processes,” Proceedings of the 38th Annual Conference of the IEEE Industrial Electronics Society, pp. 2809-2814, 2012.)

Enter software: in a paper delivered to the IEEE’s Industrial Electronics Society in Montreal last Thursday*, a group of researchers from Singapore propose a way to use low-cost sensors along with machine learning algorithms to accurately predict wear on machine parts — a technique that could cut costs for manufacturers by lengthening the lifespan of machine parts while avoiding failures.

The group’s demonstration is a promising illustration of the industrial Internet, which promises to bring more intelligence to machines by linking them to networks and integrating them with sophisticated software. Techniques from areas like machine learning, which can be computationally intensive, can thus be available in monitoring parts as small and common as cutting surfaces in milling machines.