"Internet of Things" entries

Mengmeng Chen on demystifying manufacturing

The O’Reilly Hardware Podcast: Making manufacturing accessible.

Subscribe to the O’Reilly Hardware Podcast for insight and analysis about the Internet of Things and the worlds of hardware, software, and manufacturing.

In this episode of the Hardware Podcast, we talk with Mengmeng Chen, head of U.S. operations at Seeed Studio.

Discussion points:

- Chen’s work on—and thoughts about—the Pop-up Factory, a production line that manufactured connected devices on the floor of the Solid 2015 conference

- Ways to start manufacturing in Shenzhen without a gigantic first order

- Seeed Studio’s “Open Parts Library,” a standard library of approximately 1,200 parts that can be assembled quickly and inexpensively

- Differences between the component supply chains in the U.S. and China

- Seeed’s Wio Link Kickstarter campaign

Robert Brunner on designing and building great products

The O’Reilly Hardware Podcast: The critical role of design in creating iconic products and brands.

Subscribe to the O’Reilly Hardware Podcast for insight and analysis about the Internet of Things and the worlds of hardware, software, and manufacturing.

Our expectations for industrial design have risen immeasurably in the last decade. Think of any piece of consumer electronics from 2005—a BlackBerry, for instance—and you’ll think of something that was encased in plastic painted silver to imitate metal, with a too-light heft and a rattle when shaken.

Now, nearly every successful piece of consumer hardware is the result of careful design and exquisite manufacturing. Apple deserves a great deal of credit for that shift by resetting the baseline with the iPhone in 2007, but new tools and processes have played an important role as well. Digital design has become easy and sophisticated, and contract manufacturers can do spectacular things with glass, aluminum, and semiconductors that were nearly impossible just a few years ago.

Our guest on this week’s episode of the O’Reilly Hardware Podcast is Robert Brunner, a founder of this new era of design. Brunner was director of industrial design at Apple from 1989 to 1996, overseeing the design of the PowerBook. He was the chief designer of Beats by Dr. Dre, the design-driven line of headphones that Apple acquired for $3 billion last year. And he’s the founder of Ammunition, which has worked with startups and large companies on a wide range of innovative consumer products.

Mike Kuniavsky on the tectonic shift of the IoT

The O'Reilly Radar Podcast: The Internet of Things ecosystem, predictive machine learning superpowers, and deep-seated love for appliances and furniture.

Subscribe to the O’Reilly Radar Podcast to track the technologies and people that will shape our world in the years to come.

In this week’s episode of the Radar Podcast, O’Reilly’s Mary Treseler chats with Mike Kuniavsky, a principal scientist in the Innovation Services Group at PARC. Kuniavsky talks about designing for the Internet of Things ecosystem and why the most interesting thing about the IoT isn’t the “things” but the sensors. He also talks about his deep-seated love for appliances and furniture, and how intelligence will affect those industries.

Here are some highlights from their conversation:

Wearables as a class is really weird. It describes where the thing is, not what it is. It’s like referring to kitchenables. ‘Oh, I’m making a kitchenable.’ What does that mean? What does it do for you?

There’s this slippery slope between service design and UX design. I think UX design is more digital and service design allows itself to include things like a poster that’s on a wall in a lobby, or a little card that gets mailed to people, or a human being that they can talk to. … Service design takes a slightly broader view, whereas UX design is — and I think usefully — still focused largely on the digital aspect of it.

Yancey Strickler on Kickstarter and public benefit corporations

The O’Reilly Solid Podcast: Kickstarter’s CEO on different models for viewing a company’s success.

Subscribe to the O’Reilly Solid Podcast for insight and analysis about the Internet of Things and the worlds of hardware, software, and manufacturing.

Kickstarter is one of just a handful of large companies that have become public benefit corporations — committing themselves legally to social as well as financial goals.

In making the transformation, Kickstarter’s leaders have taken a pragmatic, active position in promoting social good — neither purely philanthropic nor purely profit driven.

In this episode of the Solid Podcast, David Cranor and I talk with Kickstarter’s co-founder and CEO, Yancey Strickler, about his decision to take the company through the public benefit process and his promise not to go through an IPO.

Strickler will be among the speakers at the Next:Economy summit, November 12-13, 2015, in San Francisco.

Discussion points:

- Kickstarter’s reasoning behind its decision not to go public. Why not just sell the company and devote the proceeds to charity?

- The difference between a B corp and a public benefit corporation

- The “public good” principles in Kickstarter’s Benefit Corporation charter

- Determining metrics that can quantify public benefit goals

- Strickler’s thoughts on how Kickstarter’s PBC designation might influence a corporate model “different than hyper-growth, hyper-capitalist models that aren’t good for anyone other than people investing money”

Dialects of the IoT

How intimately we talk to our stuff depends on what it’s done for us lately.

In the first post in this series, I mentioned that we’re getting used to talking to technology. We talk to our cell phones, our cars; some of us talk to our TVs, and a lot of us talk to customer support systems. The field has yet to settle into a state of equilibrium, but I thought I would take a stab at defining some categories of conversational interfaces.

There is, of course, quite a range of intelligent assistants, but I want to consider specifically different types of conversational interactions with technology. You might have an intelligent agent that can arrange meetings, for example, figuring out attendees’ availability, and even sending meeting requests. Certainly, that’s a useful and intelligent agent, but working with it doesn’t necessarily require any conversational interaction.

Classifying conversational interfaces

As usual with these kinds of things, the boundaries can be fuzzy. So, a particular piece of technology can have aspects of multiple categories, but here’s what I propose.

Voice interfaces: Understand a few set phrases

The most basic level of speech interactions are simple voice interfaces that let you control devices or software by speaking commands. Generally, these systems have a fixed set of actions. Saying a word or phrase is akin to using a menu system, but instead of clicking on menu items, you can speak them. You find these in cars with voice commands and Bluetooth interfaces to make phone calls or play music. It’s the same kind of system when you call into a phone tree that routes you to a particular department or person. Some of these systems allow for variations in how you say something, but for the most part, they will only understand words or phrases from a predefined list.

Helping Things in the IoT speak the same language

We need to build APIs for Things that are interoperable — we need an application layer for the IoT.

Register for our free webcast “Building IoT Systems with Web Standards,” which will be hosted by Vlad Trifa and Dominique Guinard on December 8, 2015, at 10 a.m. PT.

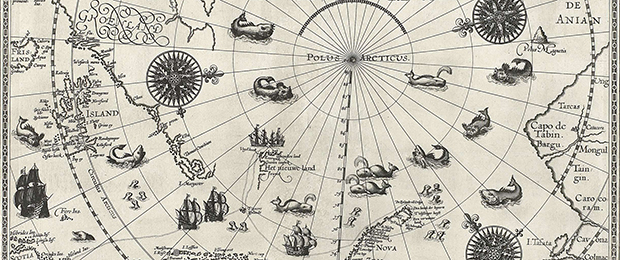

When the term “IoT” was first coined, the idea was to move from a model where data is generated by humans bridging media gaps between the physical and the virtual worlds to a model where data is gathered by the Things themselves.

Fifteen years later, we’re moving in the right direction to make this a reality, but we still have several challenges ahead. One major challenge is interoperability: many Things do talk using the Internet, but they don’t talk the same language. Having been involved in the IoT for about as long as it’s been around, I’m pretty sure of one thing: a universal networking protocol for the IoT will never exist — and for a good reason! The IoT is a vast world where the needs of one field (e.g. Industry 4.0) to another (e.g. the smart home) are fundamentally different. As a consequence, the list of automation protocols is actually growing, not shrinking.

A consequence of these different needs is the focus on the connectivity aspect of the IoT. This is not unusual, but as we ascend the pyramid of IoT needs, we must think about the data interoperability of Things. We need to build APIs for Things that are interoperable; in short, we need an application layer for the IoT.

Joe Biron on what’s new about the IoT

The IoT entails a flexible platform approach to accommodate new applications that haven’t been conceived yet.

Subscribe to the O’Reilly Solid Podcast for insight and analysis about the Internet of Things and the worlds of hardware, software, and manufacturing.

Machines have been able to talk to each other and to computers for a long time, so what’s the big deal with the IoT? That’s the first question I ask Joe Biron, my guest on this episode of the Solid Podcast. Biron is VP of IoT technology at ThingWorx, a PTC business that offers a platform for rapid development of Internet of Things applications.

Machines have been able to talk to each other and to computers for a long time, so what’s the big deal with the IoT? That’s the first question I ask Joe Biron, my guest on this episode of the Solid Podcast. Biron is VP of IoT technology at ThingWorx, a PTC business that offers a platform for rapid development of Internet of Things applications.

The answer, says Joe, is that where the machine-to-machine (M2M) model is stovepiped and specialized, the IoT entails a platform approach. Machines on the IoT are abstracted, which makes decentralized application development possible. And it’s more flexible: the platform will eventually be able to accommodate new applications that haven’t been conceived yet. Read more…

How virtual reality can make the real world a better place

Can VR become “the ultimate empathy machine?”

Virtual reality (VR) can make the impossible possible — the rules of physical reality need no longer apply. In VR, you strap on a special headset and leave the real world behind to enter a virtual one. You can fly like a bird high above Manhattan, or experience the feeling of weightlessness as an astronaut on a spaceship.

Virtual reality (VR) can make the impossible possible — the rules of physical reality need no longer apply. In VR, you strap on a special headset and leave the real world behind to enter a virtual one. You can fly like a bird high above Manhattan, or experience the feeling of weightlessness as an astronaut on a spaceship.

VR is reliant upon the illusion of being deeply engrossed in another space and time, far away from your current reality. In a split second you can travel to exotic locales or be on stage at a concert with your favourite musician. Gaming and entertainment are natural fits for VR experiences. A startup called The Void plans to open a set of immersive virtual reality theme parks called Virtual Entertainment Centers, with the first one opening in Pleasant Grove, Utah by June 2016.

This is an exciting time for developers and designers to be defining VR as a new experience medium. However, as the technology improves and consumer hardware and content become available in VR, we must ask: how can this new technology be applied to benefit humanity?

As it turns out, this question is being explored on a few early fronts. For example, SnowWorld, developed at the University of Washington Human Interface Technology (HIT) Lab in 1996 by Hunter Hoffman and David Patterson, was the first immersive VR world designed to reduce pain in adults and children. SnowWorld was specifically developed to help burn patients during wound care. Read more…

Buddy Michini on commercial drones

The O’Reilly Solid Podcast: Drone safety, trust, and real-time data analysis.

Subscribe to the O’Reilly Solid Podcast for insight and analysis about the Internet of Things and the worlds of hardware, software, and manufacturing.

In our new episode of the Solid Podcast, we talk with Buddy Michini, CTO of Airware, which makes a platform for commercial drones. We cover some potentially game-changing research in localization and mapping, and onboard computational abilities that might eventually make it possible for drones to improve their flight intelligence by analyzing their imagery in real time.

Among the general public, the best-understood use case for drones is package delivery, which obscures many other promising applications (and perhaps threatens to become the Internet-connected refrigerator of autonomous aircraft). There’s also widespread (and understandable) fear of drones. “We need to make drones do things to improve our lives and our world,” Buddy says. “That will get people to accept drones into their lives a little bit more.” Read more…

Jim Stogdill on cloud-based typewriters and smart watches

The O’Reilly Solid Podcast: Distractions, wearables, and reference peanut butter.

Subscribe to the O’Reilly Solid Podcast for insight and analysis about the Internet of Things and the worlds of hardware, software, and manufacturing.

In this episode of the Solid Podcast, David Cranor and I talk with Jim Stogdill, one of the key figures behind the launch of our Solid conference, about some of the cool pieces of hardware that we’ve come across recently.

Stogdill starts off with the Hemingwrite, an ultra-simplified Internet-connected typewriter for writers who need to isolate themselves from distraction. It duplicates, at significant expense and austerity, a small part of any modern computer’s functionality. The Hemingwrite’s existence — along with that of its oversubscribed Kickstarter campaign — demonstrates the new economics of hardware: development costs have fallen enough that clever entrepreneurs can isolate and solve niche consumer problems like needing a browserless computer because you sometimes don’t want to be distracted by your browsered computer. Also, I’d like one. Read more…