- The Shape of the Internet Has Changed — 98 percent of internet traffic now consists of content that can be stored on servers. 45% of Internet traffic today is from CDNs, and a handful of them at that, which makes CDNs like Artur Bergman’s fastly super-important. (via Donald Clark)

- Be a Good Dictator (Rowan Simpson) — There is no shortage of advice online about how to be a good designer or a good software developer. But what about advice for those who aspire to be good product dictators? Guidance seems pretty thin on the ground. […] Being a deep expert in just one area is not enough for good dictators. You need to be a polymath living at an intersection.

- Hardware is Dead — 7-inch tablet, Wi-Fi only with all the attributes of a good tablet. Capacitive touchscreen. Snappy processor. Front facing camera. 4GB of internal memory and an expandable memory slot. for USD75. At these levels there is almost no profit margin left in the hardware business. A $45 tablet is cheap enough to be an impulse purchase at the check-out line in Best Buy. A $45 price puts tablets within reach of a whole host of other activities not traditionally associated with computers. (via Steve Bowbrick)

- Car Transmissions and Syncromesh (YouTube) — cheesy old Chevy educational movie that does a great job of explaining how manual transmissions work. Such videos were the screencasts for the auto DIY folks. (via Nat Friedman)

"manufacturing" entries

Where will software and hardware meet?

Software is adding more and more value to machines. Could it completely commoditize them?

I’m a sucker for a good plant tour, and I had a really good one last week when Jim Stogdill and I visited K. Venkatesh Prasad at Ford Motor in Dearborn, Mich. I gave a seminar and we talked at length about Ford’s OpenXC program and its approach to building software platforms.

The highlight of the visit was seeing the scale of Ford’s operation, and particularly the scale of its research and development organization. Prasad’s building is a half-mile into Ford’s vast research and engineering campus. It’s an endless grid of wet labs like you’d see at a university: test tubes and robots all over the place; separate labs for adhesives, textiles, vibration dampening; machines for evaluating what’s in reach for different-sized people.

Prasad explained that much of the R&D that goes into a car is conducted at suppliers–Ford might ask its steel supplier to come up with a lighter, stronger alloy, for instance–but Ford is responsible for integrative research: figuring out how to, say, bond its foam insulation onto that new alloy.

In our more fevered moments, we on the software side of things tend to foresee every problem being reduced to a generic software problem, solvable with brute-force computing and standard machinery. In that interpretation, a theoretical Google car operating system–one that would drive the car and provide Web-based services to passengers–could commoditize the mechanical aspects of the automobile. Read more…

Investigating the growth and influence of professional Makers

We're exploring the Maker movement's role in manufacturing, business and the economy.

The growth of the Maker movement has been nothing if not amazing. We’ve had more than 100,000 people at Maker Faire in San Francisco, and more than 50,000 at the New York event, with mini-Maker Faires in many other cities. Arduino is almost a household word, along with Raspberry Pi. Now that O’Reilly has spun out Maker Media as an independent company, we look forward to the continued success of these events; they’re signs of an important cultural shift, a rejection of a prefabricated, shrink-and bubble-wrap economy that hasn’t served us well. The Make movement has proven that there are many people who want the joy of creating, whether it’s a crystal radio, a custom head for a Pez dispenser, or glowing e coli.

But the Maker movement is not just about hobbyists. We’ve seen a lot in print about the re-shoring of American manufacturing, the return of the manufacturing jobs that had been exported to China and the Far East over the past few decades. One of the questions we’re asking at O’Reilly is what the Maker movement has to do with the return of manufacturing. If the return of manufacturing just means lots of low-level industrial jobs, paying barely more than minimum wage and under near-slavery conditions, that doesn’t sound desirable. That also doesn’t sound possible, at least to me: whatever else one might say about the cost of doing business in the U.S., North America just doesn’t have the sheer concentrations of people needed to make a Foxconn.

Of course, many of the writers who’ve noted the return of manufacturing have also noted that it’s returning in a highly automated way: instead of people running around a warehouse, you’ll have Kiva robots doing the running. Instead of skilled machinists operating milling machines, you’ll have highly automated computer controlled machines with a small number of humans to test the parts and make sure they’re operating properly. This vision is more plausible — even likely — but while it promises continued employment for the engineers who make the robots, it certainly doesn’t solve any problems in the labor market.

But just as small business has long been the cornerstone of the U.S. economy, one wonders whether or not small manufacturing, driven by “professional Makers,” could be the foundation for the resurgence of manufacturing in the U.S. Read more…

Listening for tired machinery

Cheap sensors and sophisticated software keep expensive machines running smoothly

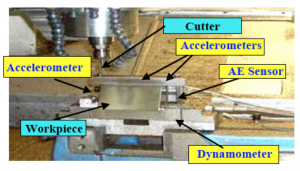

Software is making its way into places where it hasn’t usually been before, like the cutting surfaces of very fast, ultra-precise machine tools.

A high-speed milling machine can run at 42,000 RPM as it fabricates high-quality machine components within tolerances of a few microns. Excessive wear in that environment can lead to a failure that ruins an expensive part, but it’s difficult to use physical means to detect wear on cutting surfaces: human operators can’t see it and detailed microscopic inspections are costly. The result is that many operators simply replace parts on a pre-determined schedule — every two months, perhaps — that ends up being overly conservative.

The researchers’ milling machine, shown with sensors near the cutting device. (Source: X. Li, M.J. Er, H. Ge, O. P. Gan, S. Huang, L.Y. Zhai, S. Linn, Amin J. Torabi, “Adaptive Network Fuzzy Inference System and Support Vector Machine Learning for Tool Wear Estimation in High Speed Milling Processes,” Proceedings of the 38th Annual Conference of the IEEE Industrial Electronics Society, pp. 2809-2814, 2012.)

Enter software: in a paper delivered to the IEEE’s Industrial Electronics Society in Montreal last Thursday*, a group of researchers from Singapore propose a way to use low-cost sensors along with machine learning algorithms to accurately predict wear on machine parts — a technique that could cut costs for manufacturers by lengthening the lifespan of machine parts while avoiding failures.

The group’s demonstration is a promising illustration of the industrial Internet, which promises to bring more intelligence to machines by linking them to networks and integrating them with sophisticated software. Techniques from areas like machine learning, which can be computationally intensive, can thus be available in monitoring parts as small and common as cutting surfaces in milling machines.

Investigating the industrial Internet

We're working with GE to explore the coming internet of very big things.

Consumer networks have revolutionized the way companies understand and reach their customers, making possible intricate measurement and accurate prediction at every step of every transaction. The same revolution is underway in our infrastructure, where new generations of sensor-laden power plants, cars and medical devices will generate vast quantities of data that could bring about improvements in quality, reliability and cost. Big machines will enter the modern era of big data, where they’ll be subject to constant analysis and optimization.

We’ve teamed up with General Electric to explore the industrial Internet and convene a series of conversations that we hope will accelerate its development. GE’s strong presence in many industries has given it a great deal of insight into the ways that industrial data might be gathered, distributed and linked together.

Linking together big smart devices into a true industrial Internet presents enormous challenges: standards need to be developed with the full engagement of the technology industry. Software innovators will need to develop tools that can handle vast quantities of sensor data under tight security constraints, sharing information that can improve the performance of systems that have many operators — without leaking anything important to malicious groups.

Launching the industrial Internet will require big investment on the part of those who will operate each of its nodes, so in addition to looking at the concept’s technical aspects we’ll also explore its promise as a business revolution in ways that are both practical and already in use (like remote operation of mining equipment) and promising but largely conceptual (like mobile health and big data in diagnostics).

GE won’t be the only voice in this conversation: other companies have developed their own visions for the industrial Internet and we’ll be exploring those as well, looking for commonalities and engaging as many voices as we can from our neutral place in the technology industry.

The promise of the industrial Internet is that it will bring intelligence to industries that are hugely capital-intensive and create broad value that all of the industrial Internet’s participants will share. We’ll look for stories that illustrate that future.

Four short links: 20 September 2012

Distributing Content, Effective Project Dictatorship, Ubiquitous Hardware, Wheelcasts

Four short links: 24 July 2012

Big Data, Science Revealed, Web Security, and Everything's Getting Worse

- The Future of Big Data (Pew Internet) — A doubtful anonymous respondent observed, “Apparently this ‘Internet of Things’ idea is beginning to encourage yet another round of cow-eyed Utopian thinking. Big Data will yield some successes and a lot of failures, and most people will continue merely to muddle along, hoping not to be mugged too frequently by the well-intentioned (or not) entrepreneurs and bureaucrats who delight in trying to use this shiny new toy to fix the world.” Always easier to be negative than positive: if you’re wrong, nobody cares because the world is better; but if you’re right, you get to say “I told you so” as the world slides into chaos and ruin. Reminded of a politician in NZ who was said to have “predicted 8 of the last 4 recessions”. (via Jim Stogdill)

- Science in a Nutshell (Guardian) — it’s a book review, but Adam Rutherford nails the heart of science in just a few short paragraphs. (And I bought one of the books he was reviewing)

- Living with HTTPS — short rundown of the security considerations around HTTPS transported web pages.

- False Economy — it’s a political blog, but the interesting part is the table showing railway carriage mean-time-between-failures numbers for carriages bought in 1971, 1972, 1979, 1986, and 2011. Monotonically decreasing. In so many ways, they don’t make them like they used to.

Four short links: 26 June 2012

Post-Capture Zoom, Load Gen, Inventive Malware, and Manufactured Normalcy

- SnapItHD — camera captures full 360-degree panorama and users select and zoom regions afterward. (via Idealog)

- Iago (GitHub) — Twitter’s load-generation tool.

- AutoCAD Worm Stealing Blueprints — lovely, malware that targets inventions. The worm, known as ACAD/Medre.A, is spreading through infected AutoCAD templates and is sending tens of thousands of stolen documents to email addresses in China. This one has soured, but give the field time … anything that can be stolen digitally, will be. (via Slashdot)

- Designing For and Against the Manufactured Normalcy Field (Greg Borenstein) — Tim said this was one of his favourite sessions at this year’s Foo Camp: breaking the artificial normality than we try to cast over new experiences so as to make them safe and comfortable.

Foxconn and Ford, Emerson and Jobs

Considering the karmic implications of the assembly line.

Ralph Waldo Emerson's essay on "Compensation" was a source of inspiration for Henry Ford. It also affirms some of the cosmic truths Steve Jobs held dear.

Four short links: 26 August 2011

9/11 Footage, Finland's Schools, Javascript Presentations, and Hollowed-Out Manufacturing

- 911 Footage — the Internet Archive has published a great collection of video from Sep 11 2001. A tremendous boon to researchers.

- Why Are Finland’s Schools Successful? (Smithsonian Magazine) — not sure if why they’re successful is ever definitively anointed, but the article is fascinating reading.

- deck.js — Javascript presentation library.

- Why Amazon Can’t Make a Kindle in the USA (Forbes) — the progressive hollowing of manufacturing, driven by short-term gains, leading to long-term losses of industries and the corresponding areas to innovate. This is part of a series, and it’s well worth reading the whole series. (via Pinboard)

Four short links: 13 September 2010

Community Deconstructed, Sparklines Explained, NoSQL Navigated, and Foxconn Surveyed

- Open Source Community Types (Simon Phipps) — draws a distinction between extenders and deployers to take away the “who do you mean?” confusion that comes with the term “community”.

- Sparklines — Tufte’s coverage of sparkline graphs in Beautiful Evidence. (via Hacker News)

- Why NoSQL Matters (Heroku blog) — a very nice precis of the use cases for various NoSQL systems. Frequently-written, rarely read statistical data (for example, a web hit counter) should use an in-memory key/value store like Redis, or an update-in-place document store like MongoDB. I’m sure there are as many opinions as there are people, but I’d welcome a “if you want to do X, look at Y” guide to the NoSQL space. If you know of such a beast, please leave pointers in the comments. Thanks!

- The Man Who Makes Your iPhone (BusinessWeek) — a fascinating survey of Foxconn’s CEO, history, operations, culture, and plans. This line resonated for me: “I never think I am successful,” he says. “If I am successful, then I should be retired. If I am not retired, then that means I should still be working hard, keeping the company running.”