"Industrial Internet" entries

Listening for tired machinery

Cheap sensors and sophisticated software keep expensive machines running smoothly

Software is making its way into places where it hasn’t usually been before, like the cutting surfaces of very fast, ultra-precise machine tools.

A high-speed milling machine can run at 42,000 RPM as it fabricates high-quality machine components within tolerances of a few microns. Excessive wear in that environment can lead to a failure that ruins an expensive part, but it’s difficult to use physical means to detect wear on cutting surfaces: human operators can’t see it and detailed microscopic inspections are costly. The result is that many operators simply replace parts on a pre-determined schedule — every two months, perhaps — that ends up being overly conservative.

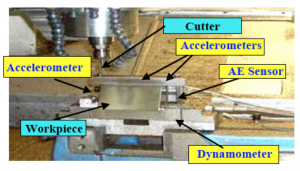

The researchers’ milling machine, shown with sensors near the cutting device. (Source: X. Li, M.J. Er, H. Ge, O. P. Gan, S. Huang, L.Y. Zhai, S. Linn, Amin J. Torabi, “Adaptive Network Fuzzy Inference System and Support Vector Machine Learning for Tool Wear Estimation in High Speed Milling Processes,” Proceedings of the 38th Annual Conference of the IEEE Industrial Electronics Society, pp. 2809-2814, 2012.)

Enter software: in a paper delivered to the IEEE’s Industrial Electronics Society in Montreal last Thursday*, a group of researchers from Singapore propose a way to use low-cost sensors along with machine learning algorithms to accurately predict wear on machine parts — a technique that could cut costs for manufacturers by lengthening the lifespan of machine parts while avoiding failures.

The group’s demonstration is a promising illustration of the industrial Internet, which promises to bring more intelligence to machines by linking them to networks and integrating them with sophisticated software. Techniques from areas like machine learning, which can be computationally intensive, can thus be available in monitoring parts as small and common as cutting surfaces in milling machines.

Industrial Internet links

Robots, railways, the Internet of very small things, and SQL injection in solar panels.

Here’s a broad look at a few recent items of interest related to the industrial Internet — the world of smart, connected, big machines.

Smarter Robots, With No Wage Demands (Bloomberg Businessweek) — By building more intelligence into robots, Rethink Robotics figures it can get them into jobs where work has historically been too irregular or too small-scale for automation. That could mean more manufacturing stays in American factories, though perhaps with fewer workers.

The Great Railway Caper (O’Reilly Strata EU) — Today’s railroads rely heavily on the industrial Internet to optimize locomotive operations and maintain their very valuable physical plant. Some of them were pioneers in big networked machines. Part of Sprint originated as the Southern Pacific Railroad Network of Intelligent Telecommunications, which used the SP’s rights-of-way to transmit microwave and fiber optic signals. But in the 1950s, computing in railways was primitive (as it was just about everywhere else, too). John Graham-Cumming relayed this engaging story of network optimization in 1955 at our Strata Conference in London two weeks ago.

Investigating the industrial Internet

We're working with GE to explore the coming internet of very big things.

Consumer networks have revolutionized the way companies understand and reach their customers, making possible intricate measurement and accurate prediction at every step of every transaction. The same revolution is underway in our infrastructure, where new generations of sensor-laden power plants, cars and medical devices will generate vast quantities of data that could bring about improvements in quality, reliability and cost. Big machines will enter the modern era of big data, where they’ll be subject to constant analysis and optimization.

We’ve teamed up with General Electric to explore the industrial Internet and convene a series of conversations that we hope will accelerate its development. GE’s strong presence in many industries has given it a great deal of insight into the ways that industrial data might be gathered, distributed and linked together.

Linking together big smart devices into a true industrial Internet presents enormous challenges: standards need to be developed with the full engagement of the technology industry. Software innovators will need to develop tools that can handle vast quantities of sensor data under tight security constraints, sharing information that can improve the performance of systems that have many operators — without leaking anything important to malicious groups.

Launching the industrial Internet will require big investment on the part of those who will operate each of its nodes, so in addition to looking at the concept’s technical aspects we’ll also explore its promise as a business revolution in ways that are both practical and already in use (like remote operation of mining equipment) and promising but largely conceptual (like mobile health and big data in diagnostics).

GE won’t be the only voice in this conversation: other companies have developed their own visions for the industrial Internet and we’ll be exploring those as well, looking for commonalities and engaging as many voices as we can from our neutral place in the technology industry.

The promise of the industrial Internet is that it will bring intelligence to industries that are hugely capital-intensive and create broad value that all of the industrial Internet’s participants will share. We’ll look for stories that illustrate that future.