"frictionless manufacturing" entries

Signals from the O’Reilly 2015 Solid Conference

Insight and analysis on the Internet of Things and the new hardware movement.

Practitioners, entrepreneurs, academics, and analysts came together in San Francisco this week to discuss the Internet of Things and the new hardware movement at the O’Reilly 2015 Solid Conference. Below we’ve assembled notable keynotes and interviews from the event.

Lock in, lock out: DRM in the real world

Author and activist Cory Doctorow uses his Solid keynote to passionately explain how computers are already entwined in our lives and our bodies, which means laws that support lock-in are much more than inconveniences. Doctorow also discusses Apollo 1201, a project from the Electronic Frontier Foundation that aims to eradicate digital rights management (DRM).

Practical advice for hardware startups

Entering the hardware space is easier than ever. Succeeding is a different matter.

Because of recent innovations in prototyping, crowdfunding, marketing, and manufacturing, it has never been easier — or cheaper — to launch a hardware startup than it is now. But while turning a hardware project into a product is now relatively easy, doing it successfully is still hard.

Renee DiResta and Ryan Vinyard, co-authors of The Hardware Startup, recently got together with Solid Conference chair Jon Bruner to discuss the startup landscape in hardware and the IoT, and what entrepreneurs need to know to build their businesses. Read more…

Mining the value of the IoT

Michael Chui on the hidden value locked within the Internet of Things.

Jon Bruner and Dr. Michael Chui recently discussed Chui’s latest research on the Internet of Things as part of our IoT Profiles Series. A full recording of their conversation is embedded at the end of this post—and it’s well worth watching—but here’s a look at a few key points that were made. Chui will expand on these ideas and debut his new report during his session, “Beyond the hype; Mining the value of the IoT,” at the upcoming O’Reilly Solid Conference (June 23-25 in San Francisco).

Comparing B2B and consumer applications

A lot of the hype surrounding the IoT is centered around consumer products, and while Chui sees tremendous value in the consumer arena, the business-to-business (B2B) market holds particular promise. “There’s double the amount of value in B2B applications as there are in consumer applications,” he says. The value, he says, “is in logistics and manufacturing and many of those applications.”

Even in consumer applications, he adds, B2B2C (business-to-business-to-consumer) applications can multiply value. ”When, in fact, the consumer health care health monitor can be connected to my provider, to my doctor, and have that continuous stream of health data actually connect up to the professional health care system, that’s where we think a lot of value can be created.” [Discussed at the 5:08 mark.] Read more…

Why the Internet of Things isn’t the same as the new hardware movement

Cheap, accessible, open hardware is driving the IoT.

![]()

The Internet of Things (IoT) has been committing a lot of buzzword imperialism lately. It’s a hot term, marching across the technological countryside and looking for rich disciplines to capture. Electronics, manufacturing, and robotics, among others, have all become dominions of the IoT. The result is that the meaning of IoT has broadened to include practically anything that involves 1. technology, and 2. something physical.

At the same time, practitioners have been trying to escape the IoT — and its early association with Internet-connected refrigerators — for years. Big enterprises that want to develop serious applications for the Internet of Things have come up with other terms for what they’re doing, like Internet of Everything (Cisco) and Industrial Internet (GE).

Let’s put a stop to this and define some boundaries. In my view, the Internet of Things is the result of a much larger and more important movement that’s about making the physical environment accessible in the same way that the Internet has become accessible over the last 20 years. I’ll call this the “new hardware movement.” Read more…

For hardware startups, technology enables scale

Turning a hobby into a company just got a lot easier.

Download a free copy of “Building a Hardware Business,” a curated collection of chapters from our IoT library. Editor’s note: this post is an excerpt from “The Hardware Startup,” by Renee DiResta, Brady Forrest, Ryan Vinyard, which is included in the curated collection.

Over the past five years, we’ve begun to witness the emergence of Maker pros: entrepreneurs who started out as hobbyists and now want to turn their creations into full-fledged companies. The difference between a project and a product is the difference between making one and making many.

To turn a project into a company, the product has to be scalable. “Making many” has traditionally been a problem of cost and accessibility; it’s historically been both expensive and difficult to manufacture. Growing a company further requires keeping costs low enough to profit, setting up distribution channels, and managing fulfillment. Over the past few years, several trends have combined to create an environment that’s mitigated those problems. This has resulted in the growth of a hardware startup ecosystem.

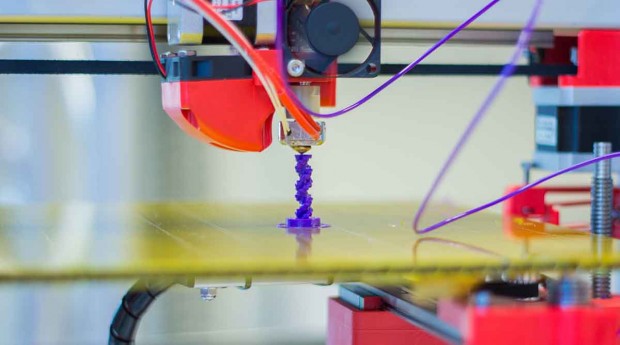

Rapid prototyping

Advances in rapid prototyping technologies have fundamentally changed the process of taking an idea from paper to the physical world. Hobbyist and prosumer-level 3D printers, CNC routers, and laser cutters have altered the landscape of personal fabrication, enabling quick and affordable iteration. While 3D printing has been around since the 1980s, the cost of a machine has dropped dramatically. Materials such as metals and ceramics enable higher-fidelity models. Cloud-based fabbing services, such as Ponoko and Shapeways, can produce a single prototype and ship it to you within a week — no need to own the printer yourself! Inexpensive boards (such as Arduino, Raspberry Pi, and BeagleBone) make electronics prototyping accessible to everyone. As interest in the Internet of Things has grown, products such as Spark Core and Electric Imp (startups themselves) have hit the market to make connected-device prototyping fast and easy. Simultaneously, computer-aided design (CAD) software has become more sophisticated, more affordable, and easier to use. Read more…

Pop-up factory

An experiment at Solid tests a manufacturing style pioneered by pirates.

A few years ago, I was lucky enough to take a tour of the South China manufacturing ecosystem with Andrew “bunnie” Huang. One of the most fascinating things that I saw there were the markets full of funny little mobile phones: Read more…

Building a hardware business

A free compilation of chapter excerpts from our IoT library highlights the approachable complexity of hardware.

Download a free copy of “Building a Hardware Business,” a curated compilation of chapter excerpts from our IoT library.

Over the last few years, we’ve seen an astonishing change in what it takes to build a hardware business. Hardware remains hard — executing it well requires technical and marketing expertise in several fields — but the barriers that startups must cross have been lowered considerably.That change has come about as a result of several changes in the way the market approaches hardware.

- Customers, whether consumers or businesses, have become aware of what hardware and connected devices can do for them. The Internet of Things means more than connected refrigerators now. For consumers, it represents desirable products like the NEST thermostat and Apple Watch. For managers, it represents the highest standards of informed decision-making and operational efficiency in everything from delivery fleets to heavy machines to simple design-driven data.

- Connecting with those customers has become easier. Startups can sell directly to niche consumers through online channels with the help of Etsy, Tindie, and ShopLocket, which are vastly easier to deal with than big-box retailers. These platforms also return rapid market feedback and offer ways for companies to connect with their consumers and build communities without intermediaries.

- Funding has become available through new mechanisms at every stage. Crowdfunding helps entrepreneurs test their ideas in the marketplace and raise enough money for early development. Venture capitalists, impressed by recent exits and aware of the vast green fields awaiting the Internet of Things, are willing to invest. Supply-chain managers like PCH are willing to take equity stakes in return for invoice financing, addressing a critical cash-flow challenge that can be a big barrier to startups looking to have products manufactured in large quantities.

The challenge of connecting anything to the Internet

The O'Reilly Solid Podcast: Zach Supalla and Will Hart on building a supply chain, making radios work, and taking on big telecom.

Subscribe to the O’Reilly Solid podcast to stay on top of topics related to the Internet of Things, hardware, software, manufacturing, and the blurring of the physical and virtual worlds.

A few weeks ago, hours after launching a blow-out Kickstarter campaign, Zach Supalla and Will Hart of Spark Labs dropped by our podcasting studio to have a wide-ranging conversation about how they’d built a successful hardware startup, how they manage their overseas supply chain, and how they’re taking on established machine-to-machine and telecom companies by turning themselves into a mobile virtual network operator (MVNO).

Zach and Will are leading a workshop at our Solid Conference called “How to manage China” on how to build and maintain a supply chain.

Spark’s latest product, the Electron, is a tiny development kit that can connect just about any kind of device to Spark’s back-end platform over a 3G cellular signal for as little as $3 per month. Read more…

Talking shop with Other Machine Company

The O'Reilly Solid Podcast: Danielle Applestone on running a machine tool startup and empowerment through desktop manufacturing.

Register for Solid 2015, where you can see Danielle Applestone’s session — How to make an Othermill: From milk jugs to your door — and much more.

An Othermill. Photo: Other Machine Co.

Grown out of the Machines that Make project at MIT’s Center for Bits and Atoms and incubated at Saul Griffith’s Otherlab in San Francisco, Other Machine Company launched a successful Kickstarter to finance completion of the Othermill back in May of 2013.

For readers not familiar with this particular type of kit, I’ll go into a bit more detail: a CNC (Computer Numerical Control) mill is a machine tool that can be controlled by a computer to move some kind of rotary cutter (such as an endmill or drill bit) to remove material from a workpiece. This is a type of “subtractive manufacturing” process.

With all of the fuss around 3D printing (known in the industry as “additive manufacturing”) these days, I personally don’t think that CNC machining gets enough attention. Although 3D printing is certainly an exciting technology in its own right, it cannot currently compete with CNC machining in terms of cost, supported material types, and range of applications. Read more…

Fixing what’s wrong with hardware startups

Five pointers to increase the odds of engineering a great hardware startup.

Attend Shahin Farshchi’s free webcast “5 Tools for Building Value Into Your Hardware Startups,” being held May 19 at 10 a.m. PT.

It is an amazing time to be a hardware entrepreneur: Companies like Arduino and ElectricImp are abstracting away tedious device and back-end development; Shapeways (disclaimer: my firm Lux Capital is an investor) and Advanced Circuits are turning around beautiful prototypes in days; while AngelList and IndieGogo are democratizing access to sophisticated investors, which in turn facilitate access to money, partners, and amazing talent.

In their rush to introduce the next Jawbone, Beats, Nest, FuelBand, GoPro, and Dropcam, many fledgling hardware startups — and their investors — seem to be simply rolling the dice. Rather than truly understanding the dynamics of their prospective markets, they are producing marketing videos that could otherwise pass for Super Bowl ads. Rather than understanding their competitive landscape, they are producing designs and out-of-box experiences that would make Steve Jobs proud. Many aspire to achieve Oculus’ visibility, and the acquisition offer that ensued. This puts incumbent consumer electronics companies in an enviable position: free market research and product experiments with an option to acquire any breakaway company. Although there is always an element of luck in every startup, here are a few pointers to increase the odds of success. Read more…