"Solid" entries

Coming up at Solid Amsterdam

A look at our unified program for unified creators.

Register now for Solid Amsterdam 2015, our conference exploring the intersections of manufacturing, design, hardware, software, and business strategy. The event will take place in Amsterdam on October 28, 2015.

Creating a great product means knowing something about many things: design, prototyping, electronics, software, manufacturing, marketing, and business strategy. That’s the blend that Solid brings together: over our one-day program at Solid Amsterdam on October 28, 2015, we’ll walk through a range of inspiration and insight that’s essential for anyone who creates physical products — consumer devices, industrial machines, and everything in between.

Start with design: it’s the first discipline that’s called on to master any new technology, and designers whose work has been confined to the digital realm are now expected to understand hardware and connected systems as well.

Design at Solid begins with our program co-chair, Marko Ahtisaari, who was head of product design at Nokia from 2009 to 2013, and is now CEO and co-founder of The Sync Project. We’ll also hear from Thomas Widdershoven, creative director at Design Academy Eindhoven and co-founder of thonik, a design studio whose work specializes in interaction and motion design. Read more…

Avoid design pitfalls in the IoT: Keep the focus on people

The O'Reilly Radar Podcast: Robert Brunner on IoT pitfalls, Ammunition, and the movement toward automation.

Subscribe to the O’Reilly Radar Podcast to track the technologies and people that will shape our world in the years to come.

For this week’s Radar Podcast, I had the opportunity to sit down with Robert Brunner, founder of the Ammunition design studio. Brunner talked about how design can help mitigate IoT pitfalls, what drove him to found Ammunition, and why he’s fascinated with design’s role in the movement toward automation.

Here are a few of the highlights from our chat:

One of the biggest pitfalls I’m seeing in how companies are approaching the Internet of Things, especially in the consumer market, is, literally, not paying attention to people — how people understand products and how they interact with them and what they mean to them.

It was this broader experience and understanding of what [a product] is and what it does in people’s lives, and what it means to them — that’s experienced not just through the thing, but how they learn about it, how they buy it, what happens when they open up the box, what happens when they use the product, what happens when the product breaks; all these things add up to how you feel about it and, ultimately, how you relate to a company. That was the foundation of [Ammunition].

Ultimately, I define design as the purposeful creation of things.

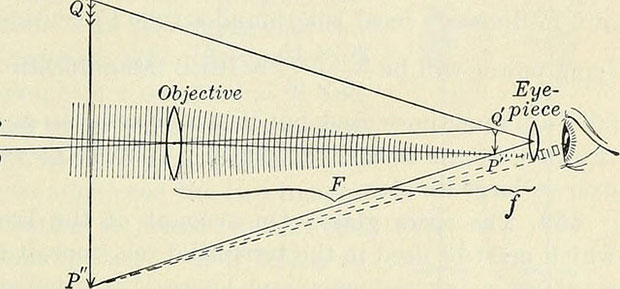

Augmenting the human experience: AR, wearable tech, and the IoT

As augmented reality technologies emerge, we must place the focus on serving human needs.

Register now for Solid Amsterdam, October 28, 2015 — space is limited.

Augmented reality (AR), wearable technology, and the Internet of Things (IoT) are all really about human augmentation. They are coming together to create a new reality that will forever change the way we experience the world. As these technologies emerge, we must place the focus on serving human needs.The Internet of Things and Humans

Tim O’Reilly suggested the word “Humans” be appended to the term IoT. “This is a powerful way to think about the Internet of Things because it focuses the mind on the human experience of it, not just the things themselves,” wrote O’Reilly. “My point is that when you think about the Internet of Things, you should be thinking about the complex system of interaction between humans and things, and asking yourself how sensors, cloud intelligence, and actuators (which may be other humans for now) make it possible to do things differently.”

I share O’Reilly’s vision for the IoTH and propose we extend this perspective and apply it to the new AR that is emerging: let’s take the focus away from the technology and instead emphasize the human experience.

The definition of AR we have come to understand is a digital layer of information (including images, text, video, and 3D animations) viewed on top of the physical world through a smartphone, tablet, or eyewear. This definition of AR is expanding to include things like wearable technology, sensors, and artificial intelligence (AI) to interpret your surroundings and deliver a contextual experience that is meaningful and unique to you. It’s about a new sensory awareness, deeper intelligence, and heightened interaction with our world and each other. Read more…

At Solid San Francisco, you could see all the way to the future

Making sense of the intersection between connected devices, accessible hardware, and synthetic biology.

Register for Solid Amsterdam, October 28, 2015 — space is limited.

I don’t usually describe conferences as “mind expanding,” but in this instance, the description is justified. At O’Reilly’s Solid 2015: Hardware, Software & the Internet of Things, held recently at Fort Mason in San Francisco, I encountered startling views of the future, thoughtful presentations on creative combinations of exciting new technologies, and warnings about what might happen if somehow it all goes wrong.

Dozens of speakers and presenters covered topics ranging from synthetic biology to augmented reality helmets to 3D printed automobiles. The audience was a mix of software developers, hardware designers, traditional manufacturers, digital manufacturers, academics, entrepreneurs, and venture capitalists keen to spot the next major tech trends.

The conference was organized around multiple tracks and themes, including data, design, software, hardware, product development, manufacturing, biology, security, technology, and startups. What follows is an overview of my key takeaways. Read more…

10 principles for sane automobile manufacturing

A new, low-impact model for manufacturing using a dematerialized approach

The current approach for manufacturing automobiles is expensive, wasteful, and energy-intensive; it hurts our environment as well as our economy. When it costs hundreds of millions of dollars to start a car factory, innovation becomes nearly impossible. As we triple the number of cars on the road in the next 30 to 40 years, the conventional approach will not be sustainable.

Dematerialization — reducing the material and energy required to build cars — is the only effective way to reduce the environmental and social damage stemming from automobiles. Dematerialization will lead to:

- Far fewer emissions from both manufacturing and operation

- Much lower material and energy inputs in manufacturing

- Dramatically better gas mileage

- Lower wear on roads

- Fewer fatalities from car accidents

By focusing on dematerialization, my company Divergent Microfactories was able to build a car with only a third of the total health and environmental damage of an 85 kWh all-electric car. The objective: drive that impact down to a quarter or less. Read more…

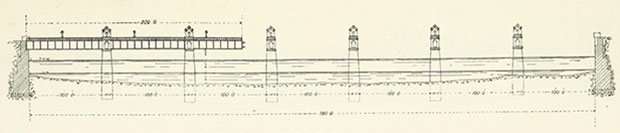

Smart building: Building bridges between IT and facilities

Building organizational bridges across the enterprise is critical to ensure successful IoT deployments.

With the proliferation of IoT-enabled systems and devices across the physical environment, the IoT is already embedded in the enterprise, often deep inside the industrial infrastructure. Generating terabytes of data, sensor-laden objects — lighting, HVAC systems, thermostats, beacons, and others — justify their cost based on the business benefits alone. Whether for energy savings, process efficiency, worker tracking, threat detection, or other purposes, facilities engineering teams are procuring these sensors and systems to address business needs. The challenge? Buildings are getting smarter without explicit or intentional involvement from IT, creating missed opportunities to leverage these assets and their data, and to align with a broader IT strategy.

While IT focuses on the computing and network infrastructure rather than the physical environment, facilities teams are deploying a new layer of smart devices across the infrastructure, without thinking that these objects are actually a series of data-generating nodes on the corporate network. To extract maximum value from these new, smart, networked devices, organizations need to redefine the historically challenged relationship between facilities and IT teams. While facility managers handle everything from plant operations, HVAC systems, maintenance teams, and snow removal, they are now also a new customer or partner for IT as buildings become instrumented. IT teams are subject matter experts and strategic partners that can ensure technology acquisitions within the physical environment will integrate with the other systems across the enterprise.

In fact, for the deployment of IoT technologies across the enterprise, there are obvious questions that IT is particularly well suited to address: Read more…

The future of car making: Small teams using fewer materials

How we make cars is a bigger environmental issue than how we fuel them.

Around two billion cars have been built over the last 115 years; twice that number will be built over the next 35-40 years. The environmental and health impacts will be enormous. Some think the solution is electric cars or other low- or zero-emission vehicles. The truth is, if you look at the emissions of a car over its total life, you quickly discover that tailpipe emissions are just the tip of the iceberg.

An 85 kWh electric SUV may not have a tailpipe, but it has an enormous impact on our environment and health. A far greater percentage of a car’s total emissions come from the materials and energy required for manufacturing a car (mining, processing, manufacturing, and disposal of the car ), not the car’s operation. As leading environmental economist and vice chair of the National Academy of Sciences Maureen Cropper notes, “Whether we are talking about a conventional gasoline-powered automobile, an electric vehicle, or a hybrid, most of the damages are actually coming from stages other than just the driving of the vehicle.” If business continues as usual, we could triple the total global pollution generated by automobiles, as we go from two billion to six billion vehicles manufactured.

The conclusion from this is straightforward: how we make our cars is actually a bigger environmental issue than how we fuel our cars. We need to dematerialize — dramatically reduce the material and energy required to build cars — and we need to do it now. Read more…

Connected machines: Taking manufacturing to the next level of IoT

Linking factory machines back to their builders creates an efficient production loop.

We’ve all seen how connected products can transform industries in areas like home energy management and personal health, and manufacturing is no exception. When products communicate back to their original makers, the manufacturers can detect production flaws well before customers would need to raise warranty claims. Further, product usage data can become the core of value delivered to the customer. Now that we have Fitbit and Jawbone UP, would you ever consider buying a traditional pedometer whose only method of telling you steps is on an LCD display? These ideas can be applied to machines on the factory floor, too.

In a previous blog post on the connected factory, I shared how Cisco’s designs combine best practices from operational technology (OT) and IT into robust and secure networks. I also addressed how wireless connectivity can enable a more effective workforce and how digital transformation with real-time production analytics improves quality.

Now, imagine extending that connectivity beyond the plant floor and internal operations by connecting factory machines back to the machine builders that created them. Manufacturing operations that rely only on data generated within the plant and shared internally are missing an important opportunity. Sharing data with the machine builders who know the machine best can create opportunities to significantly improve machine performance by making those machines smarter. Read more…

Diversity and good intentions

Supporting nonprofits that encourage diversity in the tech world.

At O’Reilly, we value diversity. At each O’Reilly conference, we choose a worthy nonprofit (particularly those that support diversity in the tech world) that we want to support. In the conference registration process, we invite attendees to make a donation to that organization, which is matched by O’Reilly Media.

Past matching donation recipients included some wonderful organizations, such as the National Center for Women & IT, Code.org, Girls Who Code, PyLadies, Anita Borg Institute, Black Girls Code, Women Who Code, and we’re currently raising money for Code2040 at OSCON.

For Solid 2015, we selected Double Union. A hacker/maker space by and for women seemed like an excellent nonprofit to get support from Solid attendees and O’Reilly.

But we made a mistake. We mentioned Double Union as the recipient of these matching donations and used their logo on the Solid Conference website, without first getting the permission of the Double Union board. That was a mistake that never should have happened.

At Double Union’s request, we’ve removed their name and logo from the conference website. We have also apologized to the Double Union board. Read more…

Seeed Studio electronics factory walkthrough

An update from the Pop-up Factory project.

As part of the preparations leading up to the Pop-up Factory installation next week at O’Reilly’s Solid Conference, Marcelo Coelho and I went to China to work with sponsor Seeed Studio’s Shenzhen facility in order to produce parts for more than a thousand Alike wristbands.

Working with Seeed project manager Vivian Zhong, we set up in a conference room for the week to organize logistics for getting neoprene straps and assembled printed circuit boards (PCBA) produced and shipped. We also worked with her to source the components that will be used for the manufacturing demonstration in the Pop-up Factory itself at Solid.

In this video, Zhong shows us what’s going on in the factory, all the way from reels of components through various assembly and testing stations. Although the factory is working on many other projects in addition to Alike, we were fortunate enough to catch up to the Alike PCBA as they were in the testing phase. Read more…